Indlela yokunciphisa ilahleko yentsimbi kubuNjineli

Eyona ndlela isisiseko kukwazi isizathu sokusetyenziswa kwentsimbi enkulu, nokuba i-magnetic vernity iphezulu okanye i-frequency inkulu okanye imibulo yendawo ibaluleke kakhulu kwaye kunjalo. Ewe kunjalo, ngokungqinelana nendlela eqhelekileyo, kwelinye icala, kuyimfuneko ukuqikelela inyani kangangoko kunokwenzeka kwi-SIMIL, kwelinye icala, itekhnoloji yolungelelaniso inciphisa iteknoloji eyongezelelweyo. Ngokweyona ndlela ixhaphakileyo kukwandisa ukusetyenziswa kwephepha le-selicon yentsimbi, iimeko ezahlukeneyo zesicelo zinemveliso engcono yemveliso.

Isekethe yemagnethi yemagnethi

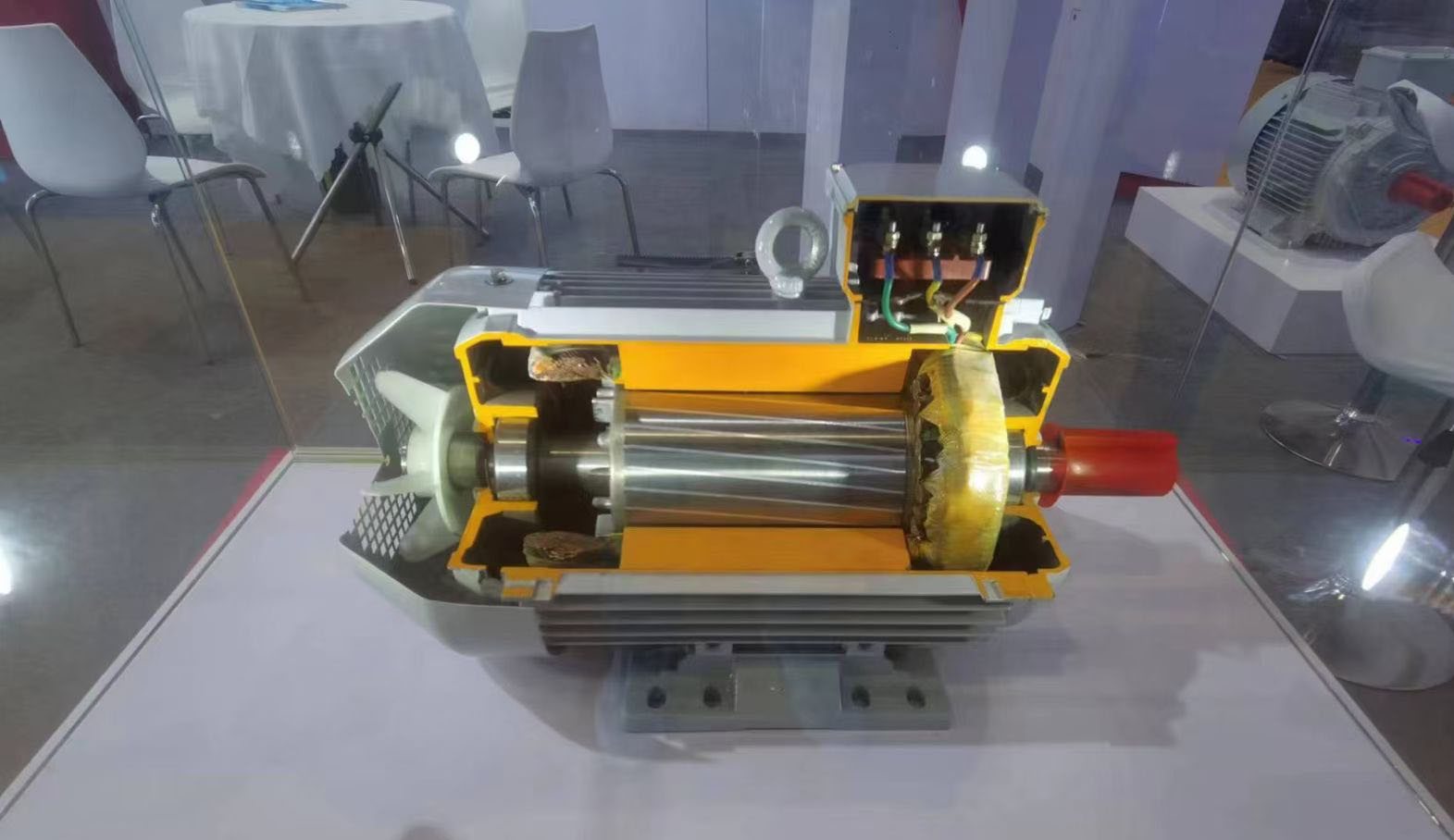

Ukulungiselela isekethe yemagneti, ngakumbi ukuqhuba iipropathi zesono zemagnethi. Oku kubaluleke kakhulu, kungekuphela nje kwi-Indetor-frequenction ye-otors. I-Prequenction Reftion I-Induction I-Ischnnchronous ibalulekile. Ndikhe ndenze i-moptors ezimbini ngentsebenzo eyahlukileyo ukuze kunciphise iindleko kumzi-mveliso woomatshini wokubhaliweyo, kunjalo, eyona nto ibalulekileyo kukuba akukho pole ye-sinidal engangqinelani nentsimi yemagneti ye-moya ye-hinemasi ye-moya yemagneti. Kuba umsebenzi ukwimeko ezisantya esiphezulu, iiakhawunti zokusebenzisa intsimbi enkulu, ke ukulahleka kweemotor zikhulu kakhulu, kwaye ekugqibeleni, emva kokusetyenziswa kwentsimbi ye-algorithm ngaphezulu kwamaxesha ama-2. Ikwakukhumbuza ukuba xa usenza isantya sokuguqula rhoqo ukulawula imoto, kufuneka udibanise i-algorithm yokulawula ukuyenza.

2.Decrease Simahla Akukho mlinganiselo

Eyona ndlela isisiseko kukwazi isizathu sokusetyenziswa kwentsimbi enkulu, nokuba i-magnetic vernity iphezulu okanye i-frequency inkulu okanye imibulo yendawo ibaluleke kakhulu kwaye kunjalo. Ewe kunjalo, ngokungqinelana nendlela eqhelekileyo, kwelinye icala, kuyimfuneko ukuqikelela inyani kangangoko kunokwenzeka kwi-SIMIL, kwelinye icala, itekhnoloji yolungelelaniso inciphisa iteknoloji eyongezelelweyo. Ngokweyona ndlela ixhaphakileyo kukwandisa ukusetyenziswa kwephepha le-selicon yentsimbi, iimeko ezahlukeneyo zesicelo zinemveliso engcono yemveliso.

Isekethe yemagnethi yemagnethi

Ukulungiselela isekethe yemagneti, ngakumbi ukuqhuba iipropathi zesono zemagnethi. Oku kubaluleke kakhulu, kungekuphela nje kwi-Indetor-frequenction ye-otors. I-Prequenction Reftion I-Induction I-Ischnnchronous ibalulekile. Ndikhe ndenze i-moptors ezimbini ngentsebenzo eyahlukileyo ukuze kunciphise iindleko kumzi-mveliso woomatshini wokubhaliweyo, kunjalo, eyona nto ibalulekileyo kukuba akukho pole ye-sinidal engangqinelani nentsimi yemagneti ye-moya ye-hinemasi ye-moya yemagneti. Kuba umsebenzi ukwimeko ezisantya esiphezulu, iiakhawunti zokusebenzisa intsimbi enkulu, ke ukulahleka kweemotor zikhulu kakhulu, kwaye ekugqibeleni, emva kokusetyenziswa kwentsimbi ye-algorithm ngaphezulu kwamaxesha ama-2. Ikwakukhumbuza ukuba xa usenza isantya sokuguqula rhoqo ukulawula imoto, kufuneka udibanise i-algorithm yokulawula ukuyenza.

4.Decrease Magnetic Delity

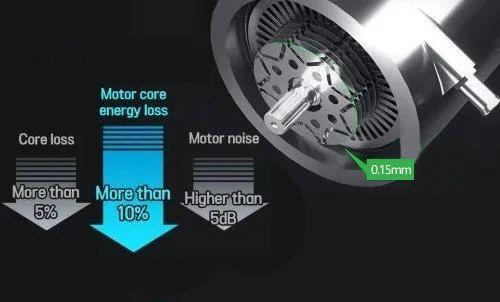

Ukonyusa ubude bentsimbi okanye ukwandisa indawo yokuqhubela phambili kwe-magnetic yesekethe yemagnethi yokunciphisa uxinzelelo lwe-magnetic flue, kodwa inani lentsimbi elisetyenziswayo liza kunyuka ngokomdlalo;

5.Ventedsuce ububanzi be-iron chip ukunciphisa ilahleko yokubanjiswa okwangoku

Ukuba i-Silicon ye-Silicon eqengqelekayo isetyenziswa endaweni yephepha le-selicon yentsimbi evuthiweyo, ubukhulu bephepha lensizi inokuncitshiswa, kodwa i-chies yentsimbi ecekeceke iyakonyusa inani leendleko zentsimbi kunye neendleko zokwenza imveliso.

6. Iphepha le-selicon elomeleleyo le-selicon eliqengqelekayo elinomngqinisiso olulungileyo lwe-magonetic lisetyenziselwa ukunciphisa ukulahleka kwe-hysteriss

I-7.7High ye-Iron yokuSebenzisa i-iron i-chip

8.Unyango lweTitshala kunye neTekhnoloji yeMveliso

9. Uxinzelelo lwentsalela emva kokuba i-Iron Chip iya kuyichaphazela kakhulu ilahleko yemoto, kunye nendlela yokusika kunye ne-shear uxinzelelo lwempembelelo yentsimbi ngexesha le-iron ye-silicon ye-ser. Ukusika kwicala eliqengqelekayo lephepha le-selicon yensizi kunye nonyango lobushushu lwephepha le-Silicon Steel linokunciphisa ilahleko ye-10% ukuya kwi-20%.

Ixesha lokuposa: I-Nov-27-2023